CHOOSING PHOTO CHEMICALS

We have a range of photo chemistry compatible for printing/processing all of our resin coated and fibre base papers in trays/dishes as well as in processing machines.

If you are new to printing the choice could appear excessive yet each liquid or powder paper developer has its purpose or strengths. For an overview of the whole range and what they do we have pulled together an introductory overview. If you are a beginner* and wondering where to get started then read on.

*While this is aimed at beginners the products are suitable for all levels of printing

Paper developers come in either liquid and powder concentrate form and have a range of attributes. Powder concentrate developers are typically more cost effective than liquid concentrates while liquid is normally quicker and easier to use making it a better choice for beginners.

When getting started we would recommend the following chemistry:

DEVELOPER – FOR DISH/TRAY PROCESSING

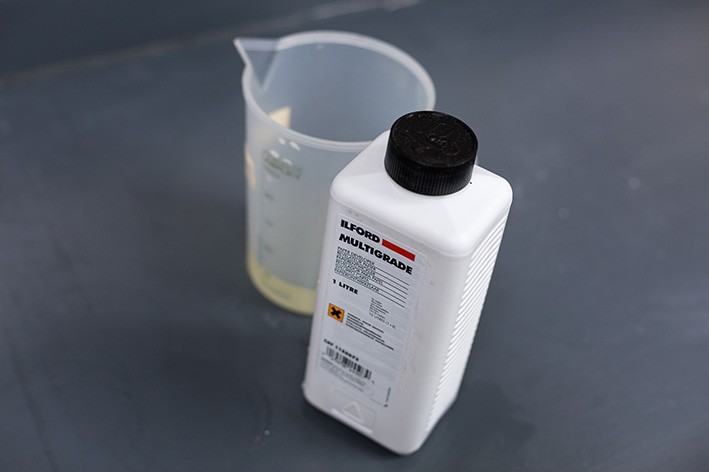

MULTIGRADE DEVELOPER offers good performance with all our paper products. It is easy and economical to use, has good keeping properties (can typically be reused) and gives a neutral image tone. Available as 500ml, 1L and 5L items, it can be used at either 1+9 or 1+14 dilutions. A 1L bottle used at 1+9 dilution should produce approximately 1000 resin coated 10×8″ prints or 500 fibre base 10×8″ prints.

If you are having your first go at printing/processing, you will find this developer very easy to dilute and use. Begin by determining the end volume of developer needed in the processing tray/dish being used.

For example if you are using a 10×8″ tray, the working solution should aim to 3/4 fill the tray. (If trays are filled higher the developer may spill over when processing the paper). Typically a 10×8″ tray would require an end volume of approximately 1L to 1.5L of developer.

To make 1L of working strength developer at a 1+9 dilution, measure out 100mls of MULTIGRADE DEVELOPER concentrate and add/stir in 900mls of water to make an end volume of 1L. (To make a 1.5L working solution at a 1+9 dilution, measure out 150mls of MULTIGRADE DEVELOPER concentrate and add/stir in 1350mls of water to make an end volume of 1.5L).

The added water should be as close as possible to the processing temperature to be used – typically this will be 20C (68F).

STOP BATH

ILFOSTOP is a liquid concentrate stop bath available as a 500ml item. It is compatible with all our paper (and film) products.

The chemistry is orange when initially being used, but will become purple when exhausted/near exhausted. ILFOSTOP has an indicator dye which detects a change in its PH. The stop bath is initially acidic, but processing activity and carry-over of developer results in it becoming alkaline.

It should be used at a dilution of 1+19. The mixing process is the same as for the developer. For example, assuming a 1L working solution is required, 50ml of ILFOSTOP concentrate would be needed to which 950ml of water would be added and stirred in to make a total of 1L. Again, the added water should be as close as possible to the processing temperature to be used.

FIXER

We recommend RAPID FIXER. This is a liquid concentrate available as 500ml, 1L and 5L items. It is compatible with all our paper and film products and used at a dilution of 1+4.

As with a liquid developer or stop bath, mixing it for use is quick and easy. For a 1L working solution, add 800ml of water to 200ml of RAPID FIXER concentrate and stir in.

For processing methods and development times please refer to the individual product pages.